By Jessica Phillips

Pharmaceuticals play an important role in healthcare, including the research and production of medications that treat and prevent illnesses. The pharmaceutical industry is the most profitable chemical industry and its growth increases by 5-6% every year, with revenues reaching over one trillion dollars worldwide in 2014. One area of considerable interest in pharmaceutical industries over the past few years has been process intensification (a chemical and process design approach that leads to smaller, cleaner, safer, and more energy efficient processes).

Catalysts have become increasingly important for the pharmaceutical industry. Catalysis reduces the amount of energy required for a reaction to take place, enabling economical and environmentally-sound manufacturing processes. Palladium-derived catalysts are particularly important in many organic transformations which are used in pharmaceutical production.

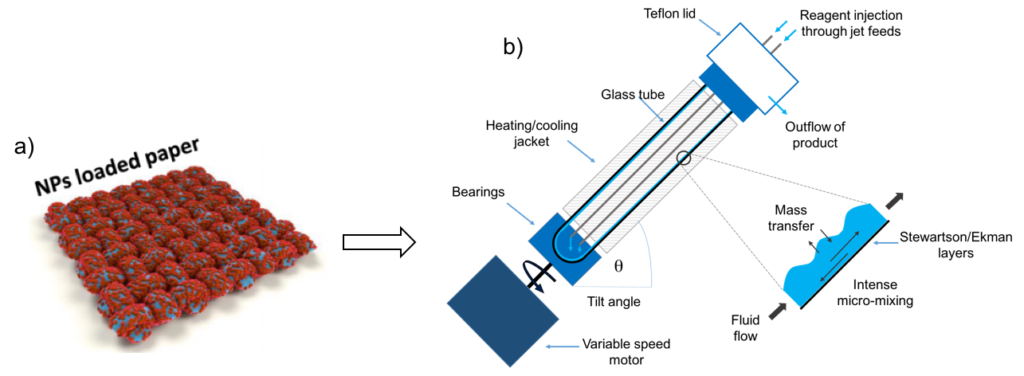

My research is exploring palladium nano-particles (NP) loaded onto filter paper for use as an immobilised catalyst within the Vortex Fluidic Device, a microfluidic continuous flow device recently developed by Professor Colin Raston. This immobilised catalyst will then be applied to the production of pharmaceutical intermediates. This will allow for the enhanced production of pharmaceutical compounds on an industrial scale and the removal of palladium, which can be potentially toxic, from reaction solutions. In addition, the low reagent and catalyst consumption leads to increased re-use of the catalyst, less waste production, reduced environmental impact, higher efficiencies, improved portability, and enables continuous product formation (rather than traditional batch processing).