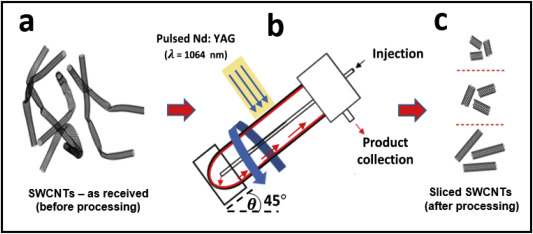

A common challenge in nanotechnology is handling and modifying objects far smaller than can be seen with the naked eye. This is the case when we want to trim carbon nanotubes down to size. Carbon nanotubes (as the name suggests) are tiny tubes, made of carbon. They are thousands of times smaller than a human hair, and have some incredibly useful properties. Using these properties often relies on nanotubes with a specific length: while short nanotubes would be best if we’re considering them for drug delivery, solar panels and other electronics will need long ones to work best. This is a problem when “as purchased” carbon nanotubes come as a tangled mess, with a broad range of lengths. How then, do you cut something you can’t see?

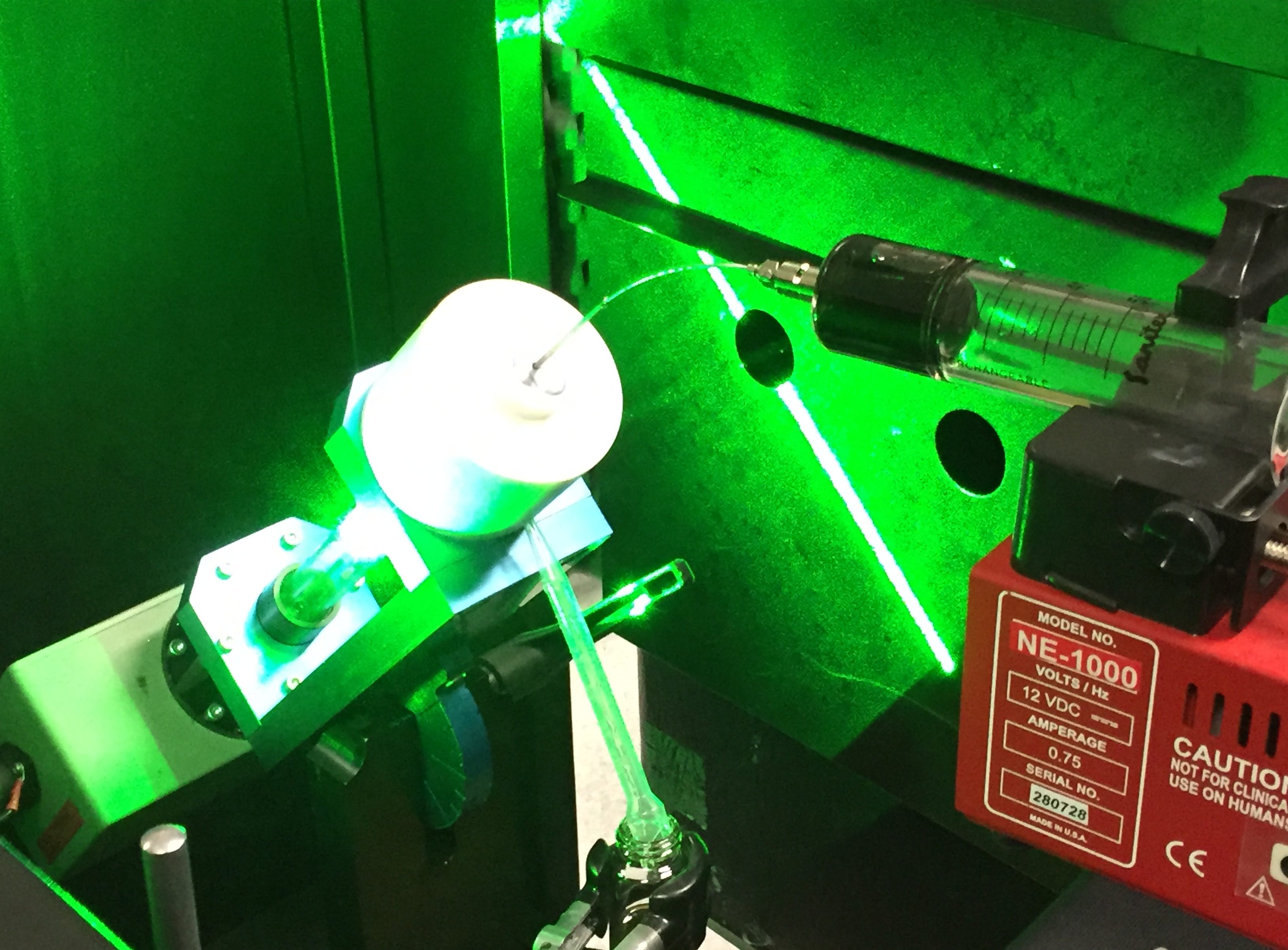

Researchers at the Flinders Institute for Nanoscale Science and Technology have come up with a solution. By combining a laser with the Vortex Fluidic Device (VFD), Thaar Alharbi (who recently returned from his time in Japan) and the rest of the team from Colin Raston’s lab, have been able to slice the carbon nanotubes to controlled lengths. By varying the laser energy used, the team were able to tune the length of the final product. Though they’re working on the milligram scale at the moment, one advantage of the VFD is it’s ability to work under continuous flow. This means the process works like a “production line”, continuously outputting the product as it is made. Using multiple devices side-by-side gives an easy way to increase the production scale. You can read the full details on the project in their article.

From eggs to nanomaterials

The Vortex Fluidic Device was invented by Professor Colin Raston. Professor Raston’s work with collaborators at the University of California, Irvine, led to the team winning the 2015 “IgNobel Prize” for their work on un-boiling an egg. The IgNobel Prize is awarded each year for research which “makes you laugh, and then makes you think”. Though it may not sound it, un-boiling an egg is seriously useful; refolding “scrambled” proteins to un-boil an egg white can also be used to refold proteins for medical applications, catalysis and more.

Other uses for the VFD have included producing drug delivery vehicles, safely producing nanomaterials, and reducing industrial waste.

This research was originally published in the journal Carbon. You can read more here.