While plastic, rubber, and ceramic materials are used almost everywhere in modern life, their responsible disposal presents a considerable challenge to society – especially for materials which cannot be recycled. This lack of recyclability drives a need for next generation materials which can be recycled.

Making any such materials a reality requires excellent control of properties such as the hardness, flexibility, colour, and transparency. New research published in Chemistry – A European Journal is tackling this problem by providing principles for controlling the properties of plastic, rubber, and glass made from waste sulfur.

“Polymers made from elemental sulfur have emerged as versatile materials for energy storage, optics applications, environmental remediation, and agriculture.” says Dr Justin Chalker, the study’s co-director, from Flinders University, “It is critical that we establish design principles to control the thermal, mechanical, and optical properties of these materials. This study provides a foundation stone for this endeavour.”

Just as PVC can be modified to make it soft and flexible for “vinyl” chair covers, or strong and rigid for use in plumbing as PVC pipe, researchers tested a range of conditions to establish the building blocks that can be used to give reliable, predictable properties to the end material. As an example, one material was made from a mixture of sulfur, canola oil, and a rigid molecule called dicyclopentadiene. Adding more canola oil to the initial reaction mixture resulted in a soft rubber, while adding more of the rigid molecule gave a harder, more durable material.

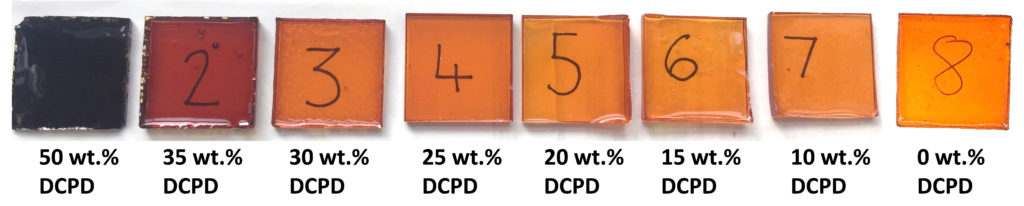

The researchers also looked at forming transparent films, with potential applications in optics including lenses, optical filters and more. This material was made by reacting terpinolene (which is an oil found in allspice and other plant products) with sulfur. By adding dicyclopentadiene to the mixture researchers were able to tune the colour and transparency of the film – ranging from transparent orange and red to black.

Other studies have reported materials similar to those explored in this study which can be broken down and reformed. This is a promising sign for the recyclability of plastics such as these, made from industry byproducts such as sulfur, and renewable building blocks like plant oils. Dr Tom Hasell from the University of Liverpool, co-director of this study, has described the work as an “important step towards taking sulfur-based polymers from a curiosity in the research lab, to a practical material that can impact everyday aspects of people’s lives.”

This study was a collaboration between Dr Tom Hasell at the University of Liverpool and Dr Justin Chalker at Flinders University’s Institute for Nanoscale Science and Technology. The lead author, Jessica Smith, carried out a portion of this work at Flinders University as part of a Royal Society-funded student exchange. Currently, Flinders PhD student Max Mann is visiting the Hasell laboratory as part of this funding. Max is studying how sulfur polymers can be used to trap valuable or toxic metals.

Other contributors to the study were researchers from the University of Birmingham and Loughborough University in the United Kingdom. Flinders researchers Max Worthington, Dr Christopher Gibson, Dr Jonathan Campbell, and Prof David Lewis were also co-authors of the study.

Further reading

Read the full paper online.

Read the original paper describing the use of limonene and sulfur to make polymers.

Read the paper on recycling sulfur based polymers online.